New Bolt Monitoring System for Wind Turbines

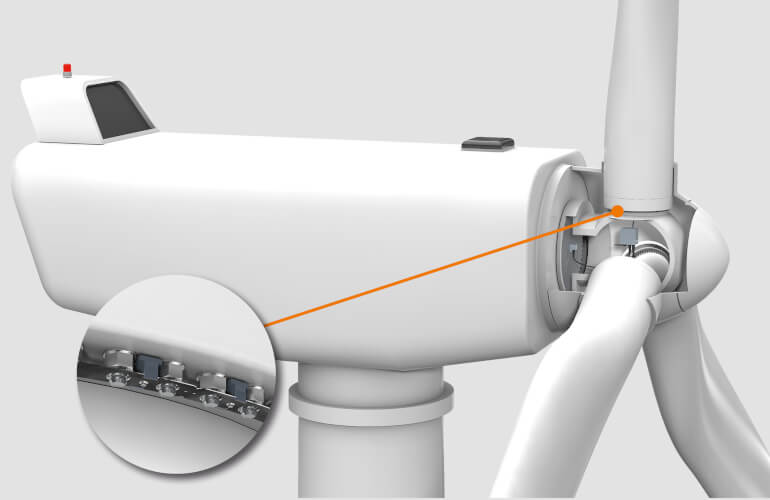

Weidmuller USA recently introduced BOLTcontrol, a monitoring system that detects broken bolts or studs in the wind blade root that connects to the hub. BOLTcontrol will alert operators immediately of any issues.

With BOLTcontrol, broken bolts are held securely in place with detection plates, which prevents consequential damage that would result if the pieces fell into the hub and ricocheted as it rotated. By continuously monitoring the rotor blade bolts, BOLTcontrol minimizes downtime, reduces repair costs and ensures the safe uninterrupted operation of the turbine.

“The bolted connections between the hub and rotor blade are constantly subjected to dynamic loads in a wind turbine,” said Pete Tecos, director of new energy solutions at Weidmuller USA. “Stud and bolt failures have become more common, and BOLTcontrol not only alerts operators to blade root fastener failures, but also prevents the fractured components from falling into the hub, thereby avoiding costly damages to pitch systems and other critical components.”

Primary benefits of BOLTcontrol include:

- Prevention of damage: Holds broken bolts securely in place to avoid damage to the hub and components.

- Ensures continued operation: Improves safety at the turbine site and a reduction of climbs needed for repairs.

- Safe and economical: Reduces downtimes and controls O&M costs by continuously monitoring the blade bolts.

- Quick and easy to retrofit: Adaptable and can be customized to different turbine types.

“Using real-time data at the site, decision-making can significantly improve with BOLTcontrol,” Tecos added. “This helps operators prioritize inspections based on conditions of the blade root connection and be one step ahead with maintenance or service needs.”

There are no comments at the moment, do you want to add one?

Write a comment