Supplying Fasteners for the New Mars Rover

TR Fastenings Norway, part of Trifast PLC, will supply rivets and tools for a Radar Imager for the new NASA Mars Exploration Rover, which launches in 2020.

“This is the first time components that TR have supplied have gone into space, and it is exciting to be a small part of future history,” the company stated.

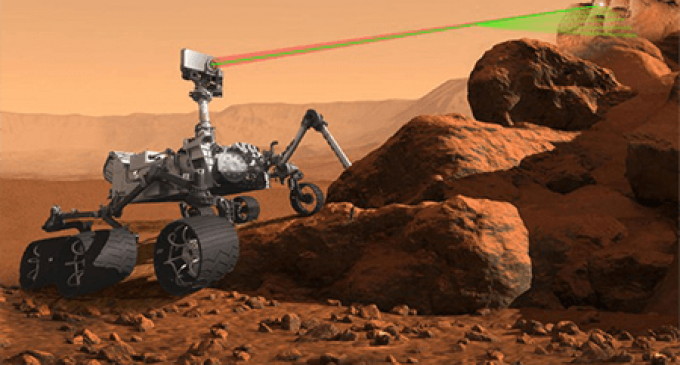

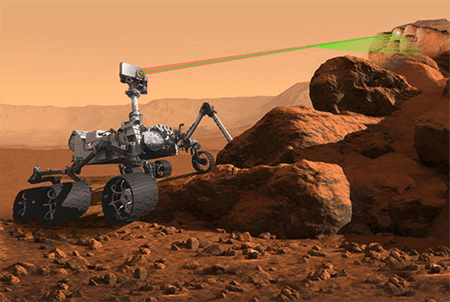

Artist’s concept of the SuperCam instrument for Mars 2020 Rover. Image Credit: NASA

The Norwegian Defence Research Establishment (FFI) which is designing and developing the Radar Imager on behalf of NASA, required components which were robust enough to withstand the extreme conditions of Mars’ atmosphere, where temperatures can plummet to minus 125 degrees centigrade. Drawing on its experience of working within the telecommunications and energy sector, TR Fastenings Norway was able to deliver the components to FFI within the required timeframe.

The Radar Image will be used in Mars’ subsurface experiment, known as RIMFAX.

“It will add a new dimension to the Rover’s toolset by providing the capability to image the shallow subsurface beneath the Rover in unprecedented detail,” stated TR Fastenings Norway.

NASA’s Mars Exploration Rover Mission is a robotic space project that began in 2003 with the sending of two solar-powered rovers to explore the Martian surface and geology.

“We are extremely proud to be involved in the development of this new Mars Exploration Rover,” commented Jan-Erik Storsve of TR Fastenings Norway. “It is incredible to think that our fasteners will be used in outer space and is a testament to the high regard our products have with such a prestigious customer as FFI.”

A spokesperson for FFI explained: “The Radar Imager for Mars’ subsurface experiment is a ground-penetrating radar experiment for NASA’s Mars 2020 Rover. The radar antenna itself is an aluminum sheet metal construction assembled from several complex shaped parts. The harsh environment during launch, landing and operation on the Mars surface necessitates strict mechanical requirements to the antenna. Furthermore, the integration with the Rover is demanding with respect to the very precise tolerances. The antenna is assembled with CherryMax® aerospace certified blind rivets and the assembly process is aided by dedicated guiding tools, all delivered by TR Fastenings.”

There are no comments at the moment, do you want to add one?

Write a comment