Panelists: Rules Can ‘Trickle Down’ to You

Michael Woznicki of Spirol Distribution explained that it isn’t just where your customers are, “it is where your customers are selling into” that can affect your company.

In one sense, it isn’t REACH, RoHS or DEHP requirements, Erich Molloy of Soule Blake & Weschler said because vendors may have to comply even if you don’t. “Our vendors will do the same thing,” Molloy said.

Rob Girdley of Würth Industry North America advised “educating your own sales people so they don’t over promise.”

Rob Girdley of Würth Industry North America advised “educating your own sales people so they don’t over promise.”

In a session on Fastener Quality & Compliance at the joint meeting of the National Fastener Distributors Association and New England Fastener Distributors Association, Girdley emphasized that “you have have to take time to review” the requirements and your product. And it has to be communicated up front. The key is good communication.”

Panel moderator Michael Lentini of Spirol Distribution said all levels of the industry must be prepared for “full material disclosure.”

Beyond materials, customers are looking to find out what chemicals are involved, Woznicki said.

One key today is software. More and more of the materials and chemicals information is available on computers, Girdley noted. For example, IMBS –International Material Data Base, is used to track chemicals.

Woznicki noted there are “only certain countries you can purchase from.”

“If you can’t trace and measure it, don’t inventory it,” Woznicki advised. “When in doubt, throw it out.”

And it isn’t just European restrictions the fastener industry needs to be aware of. For example, California’s Proposition 65 restricts lead.

Lentini added that “brass has lead in it.”

• Woznicki pointed out that if you don’t have the necessary certification paperwork, “every test can cost you $375.”

• Ultimately, “all you can do is your own due diligence with suppliers.”

• U.S. manufacturers are “not as well educated” as Europeans, Girdley finds.

You want necessary information on the P.O., Girdley advised. “It is the only solid way to comply.”

Molloy emphasized seeing the ISO compliance certificate.

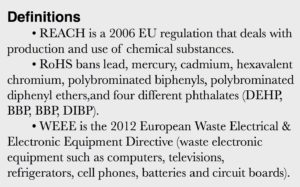

Beyond fasteners, WEEE – waste electronic equipment such as computers, televisions, refrigerators, cell phones, batteries and circuit boards – brings in service contractors and how they deal with WEEE can be crucial even though the products may never leave the U.S., Lentini said.

Lawrence Heim of Elm Sustainability Partners LLC said “the more you know about your product the more you can push back.”

There are serious issues, Molloy said. For example, DHP can seep into a person’s hand and cause cancer.

“As a supplier you have to ask the right questions. You have to establish a safe supply chain.”

There are no comments at the moment, do you want to add one?

Write a comment