Onsite Service Repairs Wind Turbine Threaded Inserts

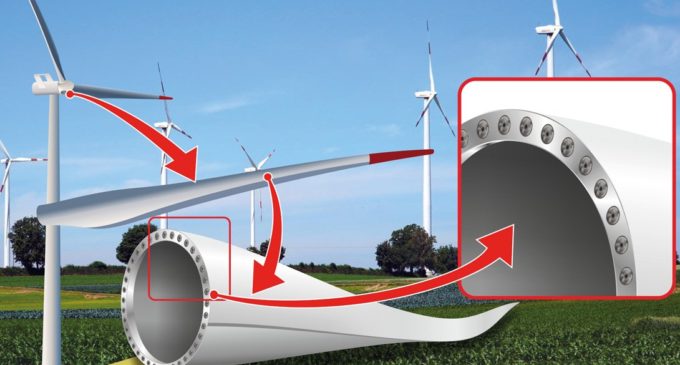

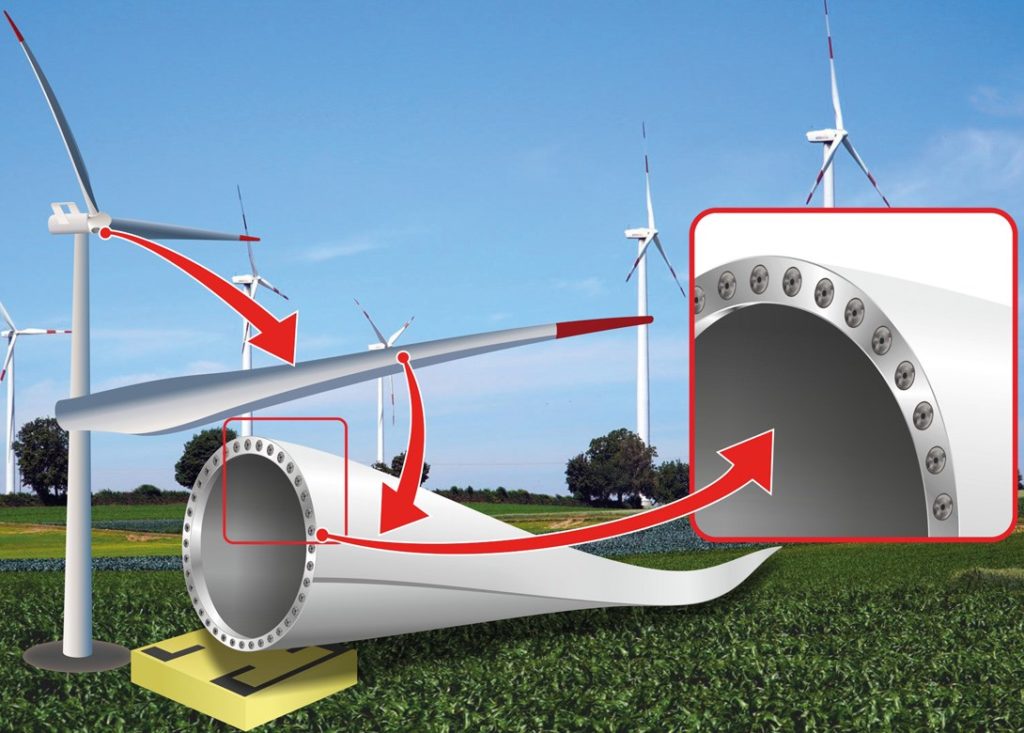

Machining specialist CNC Onsite ApS unveiled an on-site repair service and tool to replace damaged threaded inserts in wind turbine blade roots, Fastener + Fixing Magazine reports.

“The service, which takes two to three days, avoids lengthy downtime and costly logistics for the turbine operator faced with having to either transport a blade back to the manufacturer for repair, purchase a new blade, or scrap an entire turbine altogether,” writes Fastener + Fixing deputy editor Claire Aldridge.

Threaded inserts are critical for joining turbine blades to nacelle hubs but can loosen over time, weakening blade-root structural safety.

Previously, repairs had to be at a turbine maker’s facility and could take months, but now repairs can be made on-site at the wind farm.

Read the full article here.

There are no comments at the moment, do you want to add one?

Write a comment