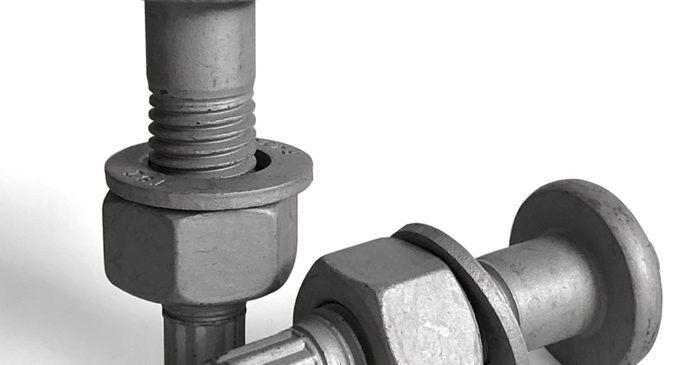

Infasco Unveils Next Gen Tension Control Bolt Coating

The following is a press release provided to GlobalFastenerNews.com. Contact the individual company for additional information.

Tension control bolts have long been a staple for a select group of fabricators and erectors. It has been my task for a number of years to get the word out on TC bolts.

The message quite often falls on deaf ears. The industry is very polarized; use them and love them or do not see the value in the product so never use them. Although the total cost of bolting is dramatically reduced when TC bolts are employed the initial bolt cost is higher pushing off people from investing. The total cost of bolting can be reduced by as much as 50% when Tension Control bolts are employed.

The message quite often falls on deaf ears. The industry is very polarized; use them and love them or do not see the value in the product so never use them. Although the total cost of bolting is dramatically reduced when TC bolts are employed the initial bolt cost is higher pushing off people from investing. The total cost of bolting can be reduced by as much as 50% when Tension Control bolts are employed.

I have been a firm believer in the simplicity of this bolting system, after snug tight simply apply the shear wrench and pull the trigger. When correctly tightened the tip shears off and the tool stops. Simple effective and just about anyone can do it (we have seen this time and time again in the bolt training we have conducted across the United States and Canada). Simple is good, simple is fast, simple is low cost.

What this very simple, effective bolting system has been missing has been a good coating system that addresses long term corrosion resistance. Well, the wait is over. Infasco has developed a system that will provide 1000 hours of corrosion resistance in a thin film coating. And yes, mechanical galvanized TC bolts are permissible but only on A325 it is not permitted for A490. The Infasco coating system, INF3013™, can be applied to both grades without any concern for hydrogen embrittlement.

I remember visiting a jobsite a few years ago and encountered a concern with mech galv bolts. The ironworker could not get the tip of the bolt to fit into the shear wrench socket. Although this was not Infasco product I explained that due to the thickness of the coating they would need to machine the socket to accommodate this thickness. The Infasco INF3013™ TC bolts are half the coating thickness of mechanical galv and have twice the corrosion resistance and still fit the socket of a typical shear wrench.

The thin film thickness of INF3013™ provides other benefits as well. At half the over tap of mech galv the thread fit up between the bolt and nut provides for free spinning of the nut onto the bolt and a higher proof load strength of the nut.

This coating system allows for very long period of corrosion resistance and good short term corrosion protection. In the case of a structural project where bolts are installed loose in the structure with bolt tightening occurring after level and plum has taking place a few days or a week later surface corrosion on black bolts can be problematic. INF3013™ coating solves this problem remaining free of corrosive products for an extended period of time.

I spend a lot of time talking about and teaching the value of uniform preload in a connection. With a solid lubricant built into the topcoat of INF31013™ this system provides more repeatable, targeted, preload than black bolt systems.

When we compare value of coating systems for TC bolts INF 3013™ exceeds performance of mech galv in many ways and does so at a cost that meets or is dramatically lower than this system.

To find out more about this revolutionary system for corrosion resistance or to review our test data, please contact the author at Rbrown@infasco.com.

There are no comments at the moment, do you want to add one?

Write a comment