Determining if a fastener will be attacked by corrosion can be a primary factor in achieving cost efficiency for long-term maintenance, according to Confast Concrete Fastening.

Fastener Industry News is marking 40 years since it was first published on July 10, 1979, a year that was dominated by a hostage situation in Iran, energy crisis, record federal expenditures, double-digit inflation and rising unemployment.

“Donning what looks like a pair of heavy duty safety goggles with a black band wrapping around the head, a technician can use images projected onto the lenses to mark the locations for 309 fasteners to be attached to a curved panel,” writes Thomas Black of Bloomberg News.

“The fact that we’re the only business in Michigan that they’re recognizing this year is pretty exciting for us,” stated Suburban Bolt marketing director Nikki Gordon.

When a thread is rolled, it means that the thread was formed by cold forming the steel by pressing the part between either two flat plates or round dies that have the thread pitch machined onto their face. As the part “rolls” through the dies, the pressure applied by the plates creates the thread without cutting or removing material.

American Elite Molding announces pay and benefits package at its Florida plant.

“If drones aren’t built right, they can break, causing potentially catastrophic results. If a fastener isn’t tightened properly, it can vibrate loose, damaging parts or completely disabling a unit,” according to Mountz Inc.

The spring of 2019 doesn’t officially begin until March 21, but the “Spring Fastener Tour” of association meetings has begun.

Half of almost 1,000 automotive industry decision makers surveyed in Europe, Asia, and the Americas believe battery electric vehicles are the No. 1 trend in their sector, up from the No. 3 spot in 2016 (and up from the No. 9 spot in 2015), according to KPMG’s Global Automotive Executive Survey 2017.

There will be five primarily distribution-oriented trade shows in the U.S. during 2019. Plus there is a re-branded machinery show.

The last time the U.S. imposed a global tariff on imported steel was in 2002 under President George W. Bush. The 30% tariff ended the following year after the WTO ruled the Section 201 remedy violated global trade practices. According to one independent study, the 2002 Bush steel tariffs cost 200,000 jobs because of higher steel prices.

The tariffs imposed by U.S. president Donald Trump dominated the front page of Fastener Industry News for 2018. But other articles included acquisitions, the FIN Fastener Stock Index, court battles, 50th anniversaries for two companies, new fastener leaders and key policy issues.

The first FIN Calendar was published in 1996 to provide one source for nearly all fastener industry organization meetings, trade shows, education and other events.

80-year-old Irish-American businessman Edward Crawford was nominated on October 22 by U.S. President Donald Trump. The White House formally sent the bid to the Senate on November 13. Crawford reportedly has family roots in Co Cork.

Media Spotlight: “We make fasteners and machines. We build machines that use our own rivets. The machine segment is about 20% of our business,” Mike Sweitzer told the Altoona Mirror.

Two-thirds would encourage people to pursue manufacturing careers. Half think of manufacturing as high-tech.

Modern system allows an extremely high productivity while maintaining high process quality. Furthermore, no building works are required for factory placement.

During FIN’s 40 years covering the fastener industry, tariffs have made frequent headlines.

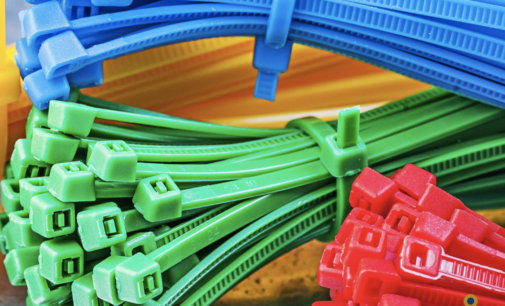

When taking the first step into finding fastening solutions, your biggest consideration will be what type of material will be required for the application.

Every engineered system has a finite service life. Even the most precise designs and robust manufacturing techniques will eventually fail. Fasteners are no different. As any engineer will tell you, it’s when these failures are unexpected or premature that it’s a problem.