Fastener – Adhesive Hybrid Improves Composite Assembly

FEATURE

Fastener – Adhesive Hybrid Improves Composite Assembly

MEDIA SPOTLIGHT: “A new fixings and fastening system for assembling structural, load-bearing composite components promises 54% better adhesion, plus less weight and better mechanical performance than current composite fixing designs,” according to Design News.

UK-based engineering and design company Adhesion Technologies Ltd. launched its Spida Fixings and fastening system, combining fasteners with adhesives to “give OEMs and their Tier 1 suppliers in aerospace, transportation, and automotive industries a cost-effective system for fast assembly of composite, engineering plastic, and metal parts, using either metallic or non-metallic fixings.”

In a press release, Adhesion Technologies said its Spida Fixings and fastening system was designed by composites engineers instead tasking mechanical engineers with designing fastening systems.

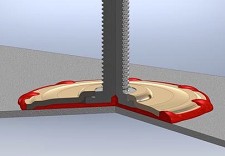

“It combines a unique base design with a proprietary adhesion technique that forms a high-strength bond to a broad range of substrate materials,” Design News reports.

Each Spida base includes a bearing area for attachments, and bases have a concave shape that forms a “micro chamber” for the adhesive, allowing the molecule structure orient from 0 to 180 degrees during curing.

“This results in enhanced peel, shear, torsion, cleavage, tension, and compressive loading.”

Specifying smaller-diameter fixings helps reduce weight and costs.

Editor’s Note: Articles in MEDIA SPOTLIGHT are excerpts from publications that show the industry what the public is reading about fasteners and fastener companies.

There are no comments at the moment, do you want to add one?

Write a comment