New Washer Measures Clamping Force

FEATURE

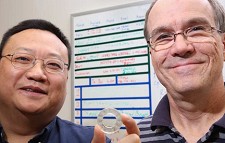

Dr. Gang Wang, left, and Dr. David (Andy) Hissam with a prototype piezoelectric washer

MEDIA SPOTLIGHT – A piezoelectric load-sensing washer provides a more accurate way to measure the clamping force exerted by the bolt it is on, the University of Alabama in Huntsville reports. That’s a benefit for numerous industries where the clamping force of bolts is critical, including construction, auto assembly, nuclear power, racing, aviation and space.

“Any performance application will have a need for this,” says Dr. Gang Wang, assistant professor of mechanical and aerospace engineering who is testing the new washer system with Dr. David (Andy) Hissam, a UAH mechanical and aerospace engineering doctoral graduate who works at NASA’s Marshall Space Flight Center (MSFC).”

Preload is generated as the bolt stretches during tightening.

“When you use a torque wrench, you are measuring torque, not the preload. You can be off the bolt’s specified preload by plus or minus 35 percent by using a torque wrench as an indicator because of the amount of friction involved, which is very difficult to quantify,” stated Hissam.

The washer uses piezoelectric filaments connected to a handheld device that registers the preload value by reading the electrical output of the filaments. Piezoelectric materials can generate a voltage when subjected to mechanical stress.

“When you tighten it up, this directly indicates how much force this washer is experiencing, which is directly related to the bolt’s preload,” Wang stated. “Instead of a plus or minus 35% variance, we are shooting for a closer range, like 5% to 10%.”

Testing involves determining an appropriate low-cost material in which to embed the piezoelectric filaments, vibration and temperature testing and trials to accumulate the data necessary to provide accurate preload readings.

“Two things we are after are accuracy and to keep the costs down,” says Dr. Wang. “We want to test so that we can be sure that when a technician tightens a bolt he gets that specific value he is looking for every time.”

Because a piezoelectric load cell is ceramic and fragile, the tests will also provide information about optimizing washer design to avoid breaking the sensing elements.

“You don’t want a force directly applied to the piezo matter; you will break it,” Wang said.

Editor’s Note: Articles in MEDIA SPOTLIGHT are excerpts from publications or broadcasts which show the industry what the public is reading or hearing about fasteners and fastener companies.

There are no comments at the moment, do you want to add one?

Write a comment