GALLOCK – Complete Safety Under Heavy Vibrations

The following is a press release provided to GlobalFastenerNews.com. Contact the individual company for additional information.

Gala Precision Engineering in India is Asia’s largest manufacturer of disc springs. Our products either meet or exceed customer expectation in terms of Quality & performance. Our GALLOCK® Wedge lock Washers have again proved our technological competency.

Continuing our legacy of manufacturing high precision engineering parts, we are glad to announce that, we at gala have successfully developed & now offer wedge lock washer GALLOCK®.

GALLOCK® washers are used to safely secure bolted joints exposed to heavy vibrations and dynamic load.

Gallock washers are used in industries like Energy generation (Wind), Off-highway applications, Heavy vehicles, Railways, Transportation, Construction and Manufacturing & processing. The number of industries that use Gallock washers is continuously growing.

GALLOCK® washers are successfully tested & approved at Indian Railways. We are the first Indian company to get approval to supply wedge lock washers for LHB & ICF railway coaches.

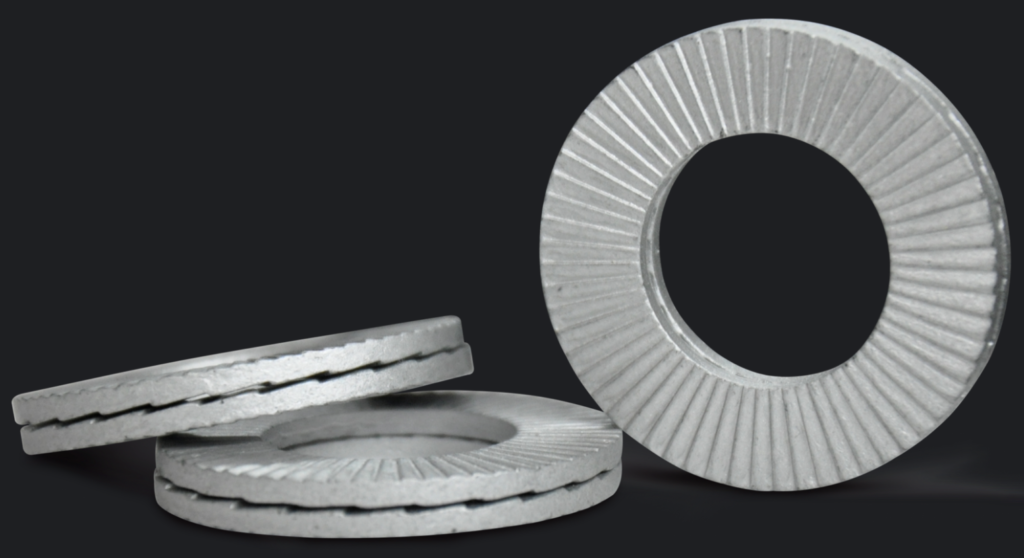

GALLOCK® consists of two flat washers having cam angled surfaces on one side & radial knurling over other side. Radial knurling on outer side of washer locks radial movement. Cam angle on inner side is designed in such a way that, cam angle is greater than bolts thread helix angle. If there is any movement along the joint, it will happen over the cam surfaces of washer. Cam surface will generate push out force within washer which leads to automatic increase of clamping force in opposite direction & prevent self-loosening.

Performance Testing & Validation in Germany

Junker test was carried out in reputed German Institute ‘IMA Dresden’. GALLOCK® washers are proven under Junker Test according to DIN-65151 standards and certified that its conformity with the requirements of the Standard DIN 25201-4.

It confirms that, GALLOCK® washers safely locks screws/bolt connections. The clamp force drop remains within acceptable limits even after 2000 cycles and just a minimal amount of tension dissipates at the beginning of the test due to the normal settlement of the fastened joint.

Junket test at IMA Dresden confirms the performance of GALLOCK® is at par with leading wedge lock manufacturers in Europe.

List of other test GALLOCK® washers successfully tested & Passed:

- Co-efficient of friction test as per ISO-16047.

- Sacrificial Cathodic Protection Test as per ISO-9227/ASTM-B117 for 72 hours.

- Salt Spray Test of Zinc flake surface coating as per ASTM-B117:2016 for 720 Hours.

- Methyl Ethyl Ketone (MEK) rub test shows no chipping of coating after 30 rubbing cycles.

We have in-house Junker testing facility to ensure we supply consistent high quality GALLOCK to our global customers. Gallock is offered with zinc flake coating to ensure long product life cycle & yielding up to 1000 hours of salt spray life. We also conduct special tests to ensure uniform coating thickness & secure adhesion of the coating on the surface.

Core Competency & Operational Excellence

Our 25 years of rich experience in blanking & forming technology, in-house tool design & development, latest software has enabled us successful lunching of GALLOCK® Washers. Our high capacity advanced technology forming presses delivers sharpness & consistency in profile resulting in optimum performance of GALLOCK® washers.

One of our major technological competencies is our world class heat treatment facility. It’s fully controlled and automated process. Some of the key features are uniform homogeneous microstructure, decarburization free surface, no quenching cracks. This enables us produce highly durable GALLOCK® washers.

About Us:

Gala have state of the art manufacturing facilities & corporate office near Mumbai in India. Our Plants are ISO-9001 & IATF-16949 certified. Company has warehouse in China & branch offices in China & Germany. We have technological ties ups with global universities for continuous product & process improvements and validations.

We serve in to variety of segments like Wind energy, hydro power, off highway vehicles, automotive, electrical, fasteners & railway etc. More than 50% of our sales contributed from exports to countries like USA, UK, Germany, France, Italy, Finland, Norway, Spain, Poland, Czech Republic, Netherlands, Denmark, China, Malaysia and Singapore etc. Our plants are audited & approved by leading global OEM’s, Fastener Distributors and Automotive Tier 1 companies. Today Gala supply our products to more than 300 customers across the globe. Web: GalaGroup.com

There are no comments at the moment, do you want to add one?

Write a comment